We offer a comprehensive line of product handling equipment to increase your production output and reduce labor costs. This includes case erectors, carton formers, vertical case transport systems (VCTS), variable speed and flexible conveyors, strappers, and accumulation tables.

Eastey Vertical Case Transport System (VCTS)

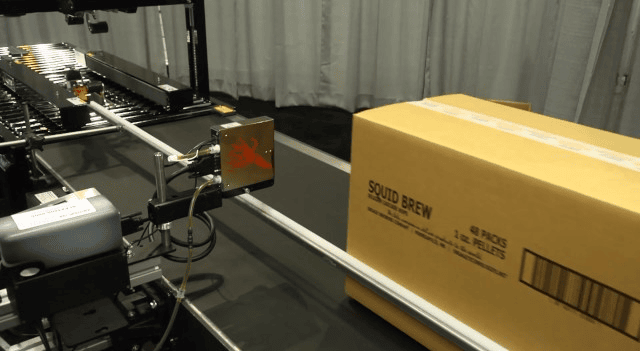

Eastey’s Vertical Case Transport System allows users to print on two sides of a case eliminating the need for pre-printed cases or expensive labeling equipment and supplies. Adjustable width settings on our standard VCTS allow users to print on cases ranging in size from 10” x 10” up to 33” x 40”. VCTS -XL allows cases ranging in size form 10” x 10” up to 48” x 40”

Designed for off-line case printing, the VCTS automatically feeds blank cases through a print station that is ideal for mounting hi-resolution inkjet printers and offers the ability to print virtually anywhere on either side of the case. Open access to printheads allows for easy maintenance and quick adjustments. The VCTS also features an input hopper that can hold up to 90 flat single wall cases and can easily be reloaded by one person.

The VCTS includes a programmable counter that keeps track of batch quantities, rate of operation, and elapsed run time, allowing users the ability to customize case runs. The system can be easily programmed to shut down when the maximum count is reached. The VCTS batch counter is the ideal solution for users looking to print a message on specific number of cases while eliminating the need for manual case counting.

Eastey ERX-15 Automatic Case Erector

The ERX-15 Case Erector from Eastey is designed to automatically erect and seal the bottom of your cases at production rates up to 15 cases per minute. The ERX 15 is designed to keep production and maintenance efforts at a minimum while providing fast, efficient case erecting, making the ERX-15 an ideal alternative to manual case forming.

The ERX-15 Case Erector enables a single operator to form, seal, and pack corrugate cases. Operation is simple: load up to 200 cases in the case magazine hopper and set your operation to run or jog mode. Separators release the leading blank case where a series of eight vacuum suction cups hold the case in a properly formed square position. After a set of stationary flap folding bars fold both minor and major bottom flaps, the case is then transitioned and the bottom is sealed with Eastey’s proven EX tape head.

The versatile design of the ERX-15 allows operators the flexibility of making adjustments on the fly without tools and easy-to-use hand tighten knobs and cranks. Need to switch case sizes? No problem, case changeover is completed in minutes for a wide range of cases as large as 19.5” in length, 19.5” in height, and 15.5” in width.

Eastey Carton Former EX-CF

The EX-CF Case Former from Eastey is designed for semi-automatic case forming and packing. The durable design has proven to keep production and maintenance efforts to a minimum to improve your case packing process. The EX-CF Case Former provides a fast and cost-efficient alternative to manual case forming.

The EX-CF Case Former enables a single operator to form, pack, and seal corrugate cases. Operation is simple: open the case and place it in the top of the case former. Pneumatic switches activate the machine’s flap folding mechanism to fold the bottom major and minor flaps. Once the flaps are folded, the case will stay in place while the case is filled by the operator. Filled cases can then be advanced into a taper for automated top and bottom case-sealing.

EX-CF Case Former offers fast and easy case size changes with adjustable hand-crank side rails to accommodate boxes 7.5” to 25” in length, 5.5” to 20” wide, and 3” tall and greater.

Eastey Accumulation Tables

Eastey’s variable speed accumulation tables are an ideal solution for product accumulation or surge back-up. Models are available in 36” or 48” diameters.

Eastey’s accumulation tables are used to temporarily stop, hold, and release bottles, cans, jars, or other containers after they are filled or cleaned. Eastey’s accumulation tables are an efficient method to balance production line rates, allowing production to continue while downstream product is halted. They also facilitate product removal for packing and prevent product damage that can occur when a production line is stopped.

TT36 and TT48 accumulation tables offer the quality that you have come to rely on from Eastey. A stainless steel turntable, variable speed motor, dual direction drive, and simple design make Eastey’s accumulation tables a workhorse that will stand up to your toughest challenges. Each table is framed with tubular steel to withstand even the most rugged applications. A powder coated exterior protects the machine base from abusive conditions and guarantees years of use. For food applications, an optional stainless base is available.

Eastey Semi-Automatic Strapper EXS-100

The semi-automatic EXS-100 strapping machine is designed to apply a plastic strap around your packages, preventing them from opening during handling and transit. The EXS-100’s bottom seal design is an ideal solution for low to medium volume users that need additional security beyond case taping.

Operating the EXS-100 strapping machine is easy and can be learned in minutes. The machine features an open cabinet design making it easy to view and change your poly strapping. The EXS-100 features electronic tension control, allowing the user to adjust the proper tension for a wide variety of packages, and the heated strap-weld sealing system ensures a secure strap.

The system comes standard with four locking casters that allow for easy transportation within the facility. The EXS-100 is pre-configured to an industry standard height of 30”, making a comfortable fit for most packaging environments.

Conveyors

We carry a variety of conveyors to fit different application needs. These include variable speed conveyors, flexible conveyors, as well as bottomless conveyors.

Eastey Variable Speed Conveyors

Eastey’s EC1248 and EC1848 variable speed conveyors offer the quality that you have come to rely on from Eastey. The EC1248 and EC1848 conveyors offer a reliable stand-alone product transport for primary or secondary product marking, and make a convenient add-on infeed or exit feed conveyor to existing case taping or shrink wrapping equipment.

EC1248 and EC1848’s design is perfect for integration with ink jet printing equipment. Each conveyor comes pre-drilled in multiple locations to easily add printer and encoder mounting brackets. The smooth drive belt provides consistent speed for reliable, scannable barcoding and product transfer. Systems include a lower shelf with holes for cable management and provide storage for supplies such as spare printheads, printer and UV LED control boxes, spare ink, and more.

EC1248 and EC1848 utilize an endless belt with self-tracking V-groove for consistent alignment. The variable speed drive motor is adjustable up to 100 fpm for a variety of applications. The unit also features a magnetic control box that can be mounted on either side of the conveyor. Conveyor legs are adjustable from 20” up to 33.5”. The system is designed to keep maintenance to a minimum and provide a fast and efficient method of product transport.

Eastey Flex Conveyor

Proven reliable over and over again, these professional level Eastey Flexible Conveyors provide you with all the quality features needed for your day-to-day operation. They are designed and built to give you all the performance features needed to transfer your lightweight or heavy packages.

Eastey Professional Flexible Conveyors are designed with all-steel construction and designed for unmatched structural integrity. Eastey’s conveyors are adjustable in height ranging from 19.7” to 31.5” (500mm – 800mm) high, and extendable in length from 59” up to 177”(1500mm – 4500mm). The flexible conveyor design allows for 180 degree return conveyor configuration. See for yourself why EASTEY has been a leader in the shrink packaging industry for over 25 years.

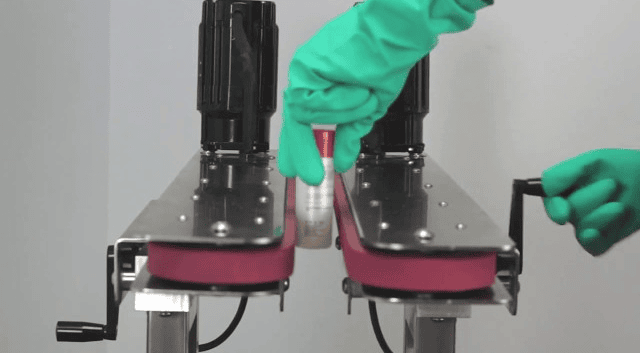

Globaltek Bottomless Side Belt Transfer Conveyor

The Globaltek Bottomless Conveyor has variable speeds and is used in moving containers a short distance from one working/transportation conveyor to another. Designed to access the bottom side of the container for coding expiration dates, lot numbers, etc. The Gripper Belts are independently adjustable using an easy adjust handle wheel, accommodating containers up to 8″ in diameter.

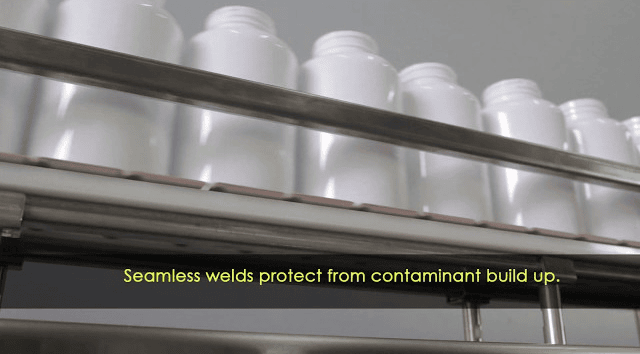

Globaltek Stainless Steel Inline Conveyor

The Globaltek sanitary conveyor is intended to minimize chances of bacteria growth due to spilled product on conveying line. In order to achieve this; this conveyor features a raised table top plastic belt to avoid buildup of unwanted debris underneath the belt. For instance, this will ensure ease wipe down when maintenance and sanitation are required.

This conveyor has many features built for food industry and plant specific needs in order to ensure food safety. Moreover, the food and beverage industry, this conveyor is great for; chemical, pharmaceutical, nutraceuticals industries as well.

This sanitary design will save you time and effort as it will not require any disassembly like most conveyors do when cleaning is required.

sales@marktecprods.com

sales@marktecprods.com