Thermal Transfer Overprinters for In-Line Printing & Coding

Thermal Transfer Overprinting (TTO) is today’s cleanest, most effective way to print variable date codes, barcodes, text and graphics on flexible packaging film, labels, pouches, sheets, card stock and other materials. Unlike other inkjet technologies, thermal transfer overprinters come in direct contact with the substrate, which allows for better quality text, graphics and barcodes.

This technology works by transferring ink onto a flexible substrate from a coated thermal ribbon that is positioned between the thermal printhead and substrate to be printed on. This ribbon is covered with a formulation of either wax, wax/resin, or resin, depending on the coding requirements. Printing elements in the printhead are then precisely heated so the ink on the ribbon melts, and then pressed against the ribbon to transfer ink to the substrate. The ink cools rapidly and that results in a permanent print on the packaging. There are no solvents used in a TTO.

Thermal transfer overprinters are easily integrated into most forms of labeling and packaging machinery such as flow wrappers, horizontal/vertical form, fill, and seal machines, confectionary thermoform, and tray-sealing machines. FlexPackPRO TTO printers can print in either a continuous or intermittent operation mode. FlexPackPRO’s line of mid-priced, high-resolution TTO coders and specialty systems leads the industry in performance, variety and value.

FlexPackPRO® 130 Series 32mm

Small, economical, high-performance TTO coders for traditional date and lot coding on flexible packaging and labels. Perfect for small packaging machines and labelers.

- 32mm (1.3”) wide, 300dpi Printhead

- Continuous & Intermittent models

- Perfect for “small footprint” expiration dates and lot codes

- Economical digital upgrade from hot stamp printers and roller coders

- Recommended for both packaging machines and labelers

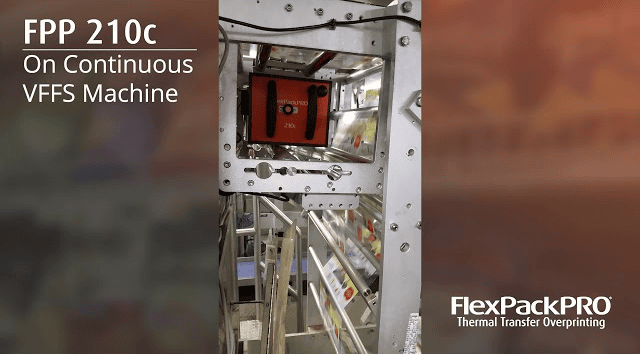

FlexPackPRO® 210 Series 53mm

Among the most popular TTO printers on the market, FlexPackPRO® 210 Series coders provide high-resolution barcodes, date codes, text and graphics in virtually any packaging and labeling environment.

- 53mm (2.1”) wide, 300dpi Printhead

- Continuous & Intermittent models

- Print “press quality” Best By dates, lot codes, barcodes, text and graphics

- High-speed performance for heavy volume applications

- Superior, cost-effective replacement for other brands of TTO

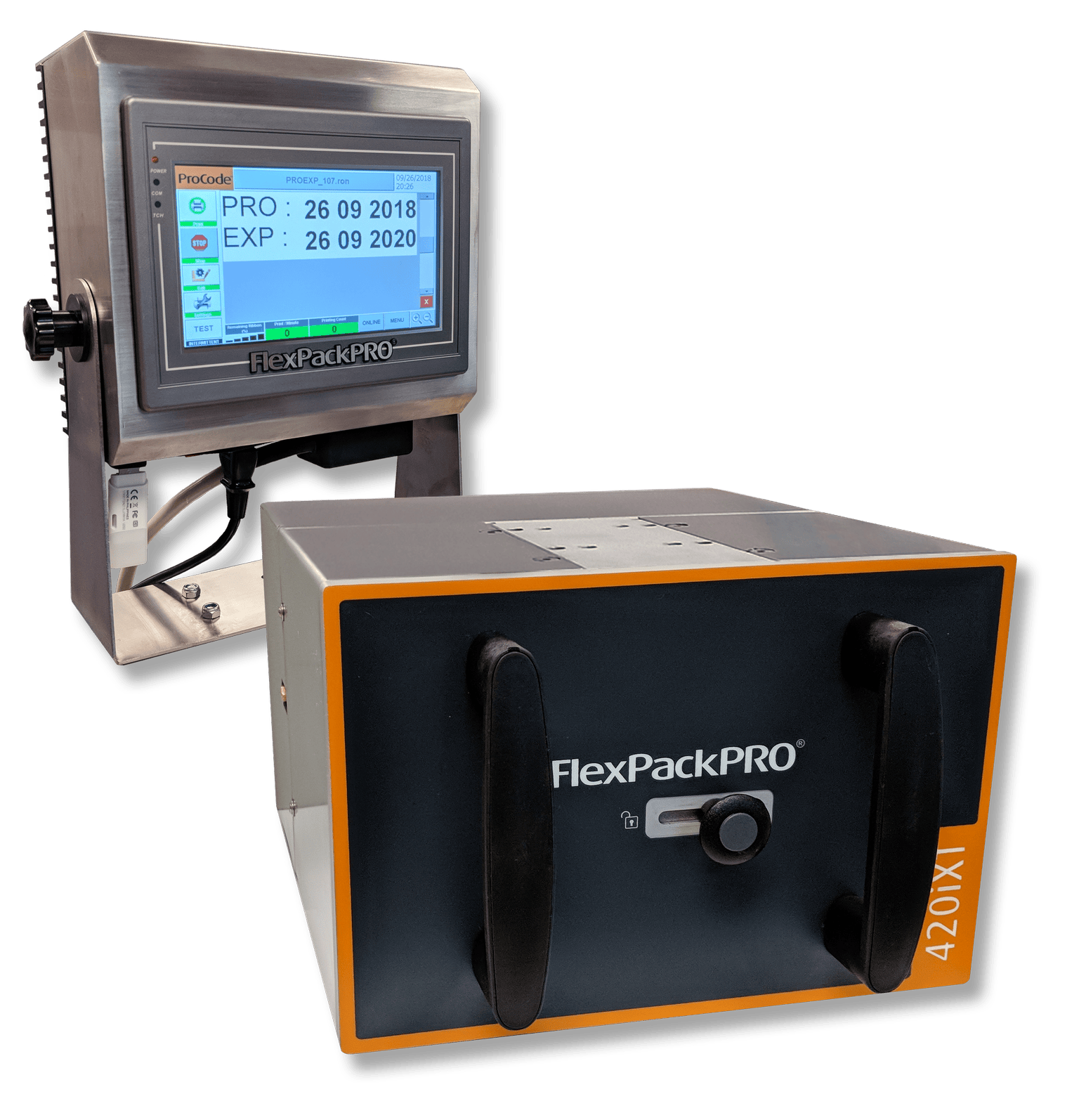

FlexPackPRO® 420 Series 107mm

For those applications requiring larger format codes, text and graphics, there is no better combination of performance and value than these outstanding 4.2” wide Thermal Transfer Overprinters.

- 107mm (4.2”) wide, 300dpi Printhead

- Continuous & Intermittent models

- Print larger combinations of codes, logos, text and graphics

- Excellent option for printing variable ingredients and nutrition panels

- Up to 4.2” x 10” print area

FlexPackPRO® 500 Series 128mm

- 128mm (5” wide), 300dpi Printhead

- Continuous & Intermittent Motion

- Largest Available TTO Print Area (5” x 8”)

- Fit logos, barcodes, date codes, ingredients, nutrition statements and more in one template

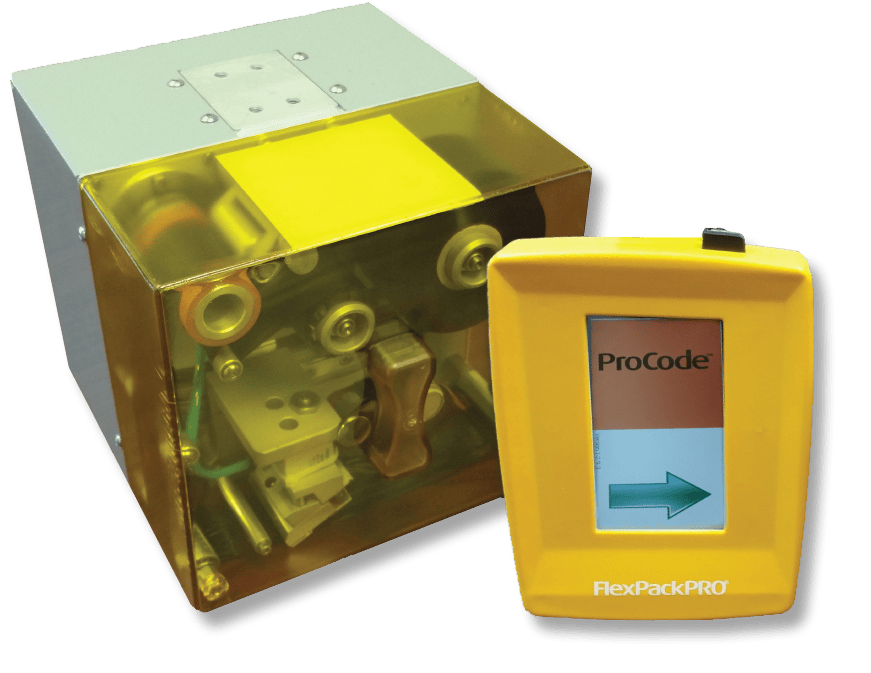

FlexPackPRO® XT Series Next Generation TTO

FlexPackPRO®32mm & 52mm All-Electric

For low-volume applications in smaller facilities with little or no access to compressed air, these cost-effective, all-electric TTO units get the job done.

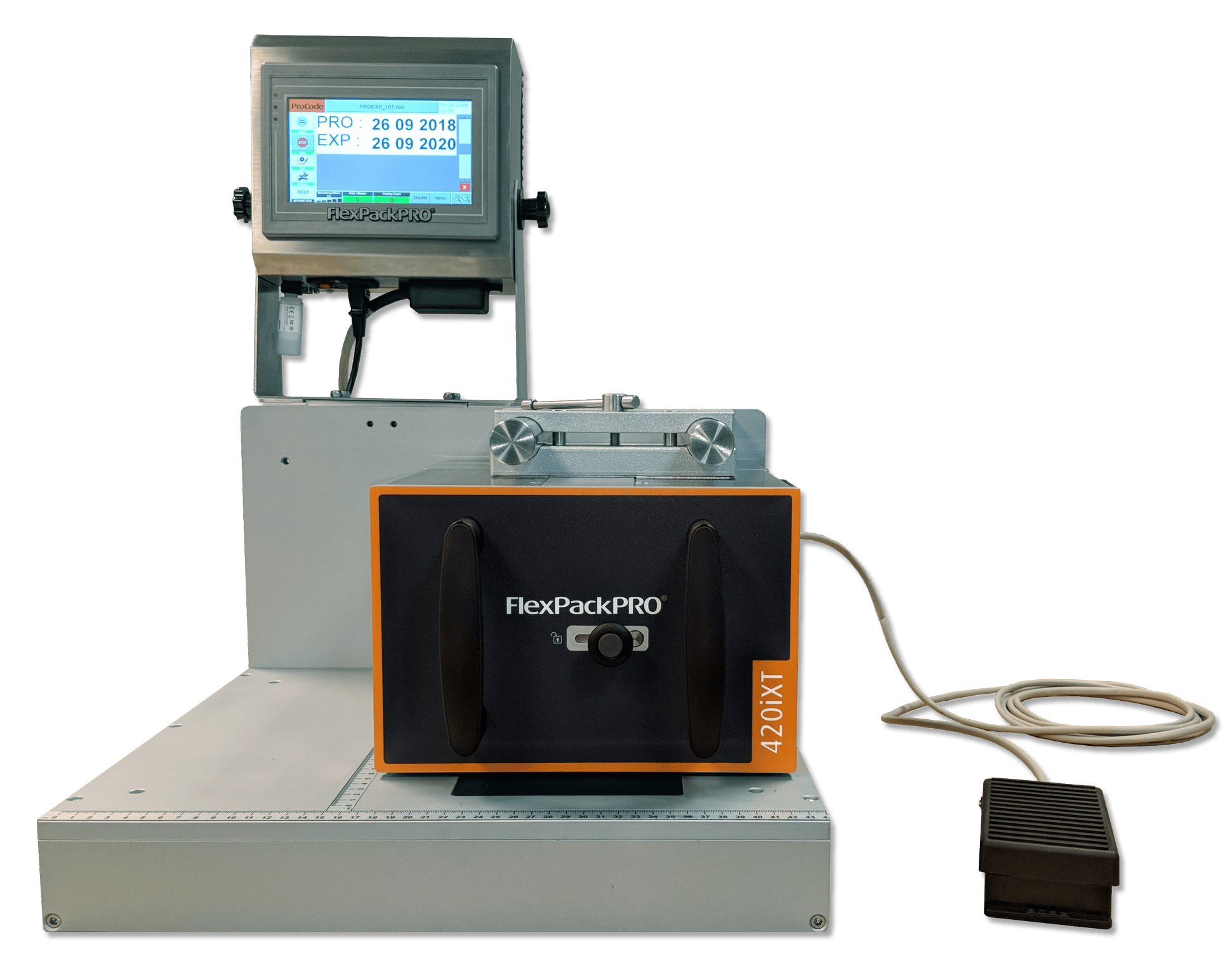

Thermal Transfer Overprinters for Offline Printing & Coding

In addition to the broadest offering of in-line TTOs, FlexPackPRO® offers the versatility and superior print quality of Thermal Transfer Overprinting in a number of cost-effective, off-line variable printing and coding systems as well. Print pouches, sleeves, cards, envelopes, bags and flexible packaging film on-demand and offline with one of FlexPackPRO’s cost-effective stand-alone solutions.

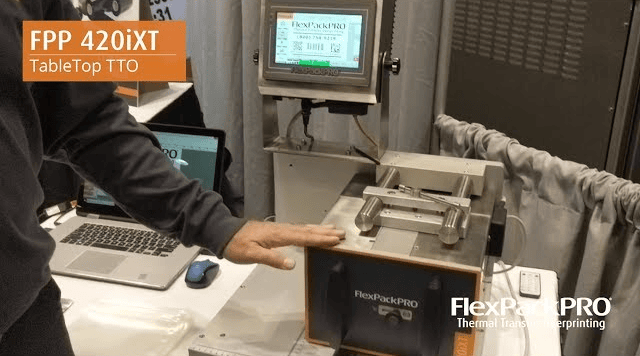

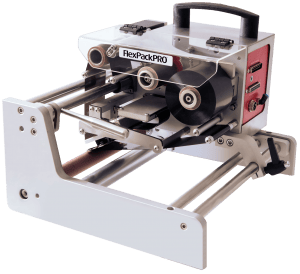

FlexPackPRO® TTS Tabletop Systems

Get the benefits of high-resolution digital on-demand printing and coding in a compact, manual TableTop TTO system. Print variable date codes, barcodes, logos, text and graphics directly onto bags, pouches, cards, tags, chipboard boxes and more. Integrated foot pedal triggers print.

Available with various 130, 210 and 420 Series TTO printer models, providing print areas of 1.3” x 2” / 1.3” x 2.75” / 2.1” x 2” / 2.1” x 3” / 4.2” x 3” / 4.2” x 5”. Print samples provided upon request.

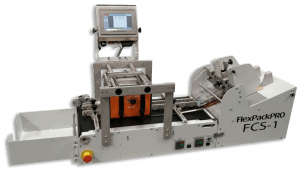

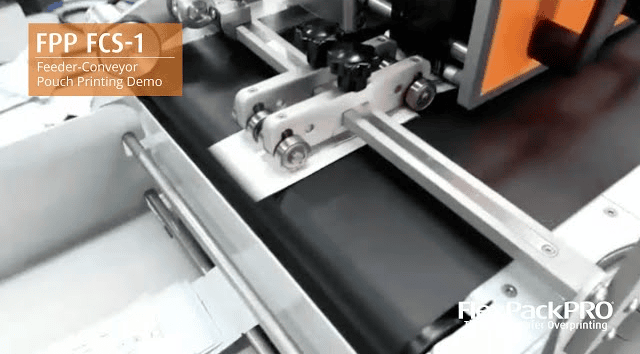

FlexPackPRO® FCS Mounted Feeder-Conveyor System

FCS-1: The rugged, cost-effective solution for printing date codes, barcodes, nutrition facts, ingredients, logos and other text and graphics on-demand. A friction feeder and short conveyor with average print speed of 30 pieces per minute. Print area from 32mm x 50mm (1.26” x 1.97”) to 107mm x 75mm (4.22” x 4.93”), depending on printer model.

FCS-2: The advanced choice for automatic feeding and printing of virtually any type of bag or pouch, up to 15” x 15” in size. Highly reliable vacuum pick and place system on wide belt feeds and prints up to 60 pieces per minute in continuous motion. Print area from 32mm x 125mm (1.26” x 4.93”) to 107mm x 125mm (4.22” x 4.93”), depending on printer model.

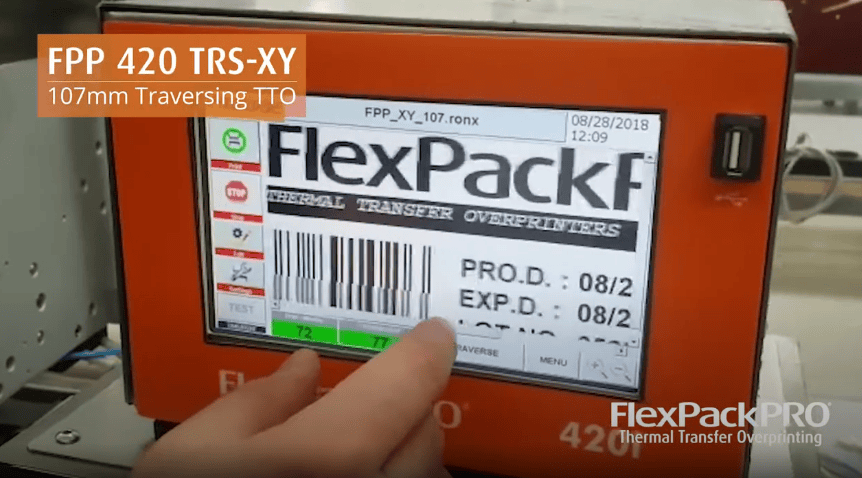

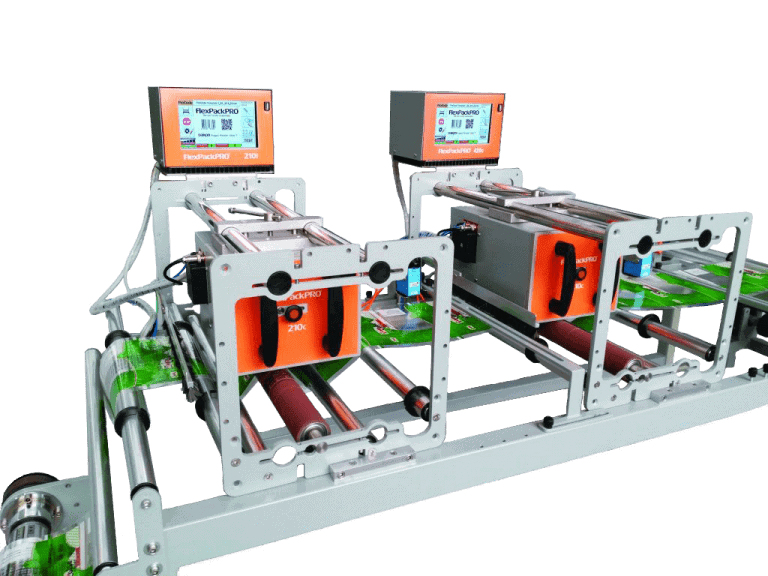

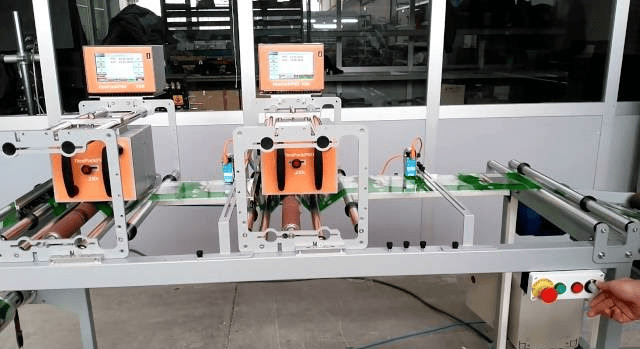

FlexPackPRO® TRS Multi-Lane Traversing

Available with a 53mm (2.1”) or 107mm (4.2”) wide printhead, the FlexPackPRO® Traversing TTO system prints high-resolution codes, text and graphics on multi-lane packaging machines. Perfect for therform, fill and seal machines requiring multiple images across the packaging film web, these units print up to 16” across in one sweep. Available with both standard and X-Y motion mounting systems.

FlexPackPRO® URS Multi-Unit Unwind-Rewind System

Reduce preprinted flexible packaging inventory with a custom-built, TTO-mounted, high-speed unwind-rewind system. Multiple TTO units can be positioned to print variable information, graphics and barcodes at different locations across the web of the roll, allowing you to customize generic packaging film

on-demand. Up to four individual FlexPackPRO TTO units can be integrated into one system (130, 210 and 420 Continuous models).

FlexPackPRO® Autobagger

Our Autobagger TTO models are specially designed to integrate easily into most stand-alone autobagger systems!

Rather than dealing with the expensive and tedious task of labeling products after they’ve been bagged, you can now integrate continuous TTO printing and coding directly onto your autobaggers, saving significant time and money. It’s also an excellent, cost-effective alternative to other autobagger printer modules.

sales@marktecprods.com

sales@marktecprods.com