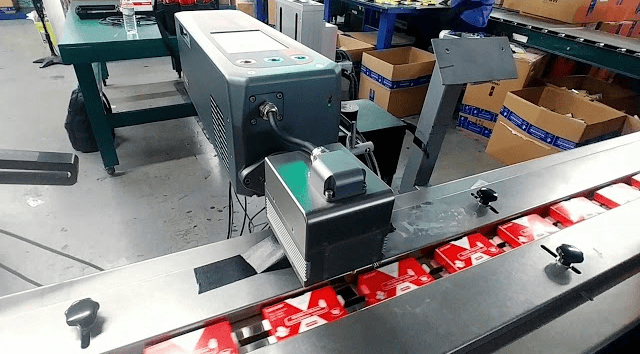

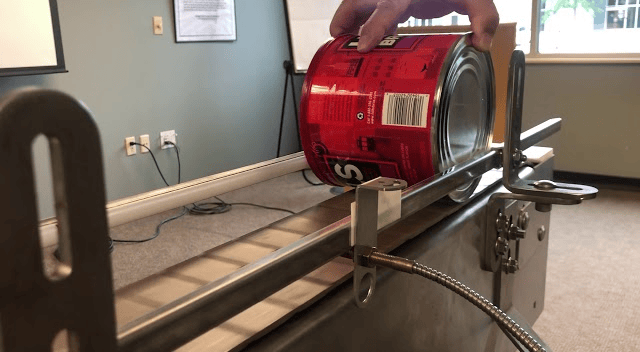

Laser coders are an ink-less way to permanently mark and code a wide selection of surfaces at low and high speeds.

- Permanent mark – can’t be removed, won’t fade, high-quality image.

- Eliminates virtually 99% of line downtime for daily maintenance.

- Immediate startup if not used for a period of time. No clogging issues.

- Lowest cost per mark and the lowest cost of ownership, no ink or solvent, no costly annual ink module to replace. Lasers just use electricity.

- Eco-friendly, no solvents, no VOC’s, HAPS removed by fume extractor.

- Easy to learn, use, and maintain.

- Available in 10, 30, and 50-watt configurations depending upon the surface.

Laser coder marking includes color change as a result of a chemical reaction between laser and product (usually on PVC), engraving of the surface, color removal of the surface coating ink on chipboard and folding cartons to reveal the white color underneath, carbonization or controlled burning of wood or board based materials which replaces costly branding irons which require a product to stop to be marked, and ink jets operating near wood dust that can enter the ink system, and the melting of different plastic materials to achieve ether a raised or concave effect. With virtually no maintenance (except wiping off the lens periodically) and no need for consumables (except electricity), the elimination of flammable ink jet fluids and solvents, laser marking provides the lowest total cost of ownership compared to other printing technologies. Lasers do not use solvents so they do not emit VOC’s. Lasers eliminate up to 95% – 100% of all line downtime and maintenance labor for daily and scheduled maintenance of ink jet printers. There are no costly annual ink changeout modules required. Fume extractors with changeable filters are used to remove any vapors and HAPS created by the laser etching process. Guarding is used to protect operators.

sales@marktecprods.com

sales@marktecprods.com