A semi-automated label applicator is a machine that has an operator place a product into a fixture or jig assembly, then the applicator affixes the label using a foot pedal or sensor located within the machine.

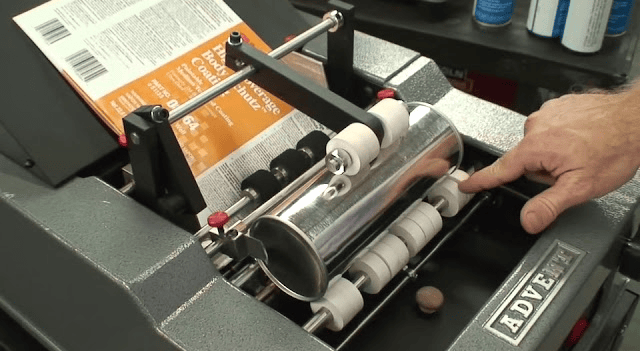

Advent Model 200

The Advent Model 200 automatically applies glue to only the ends of the label with its standard “end gluing feature” that requires no adjustment for different length labels. The machine does it automatically. What’s more, this “skip-glue” feature is a standard component on the 200. Though Advent Labelers are considerably less expensive than other comparable labelers on the market, quality and dependability are first rate.

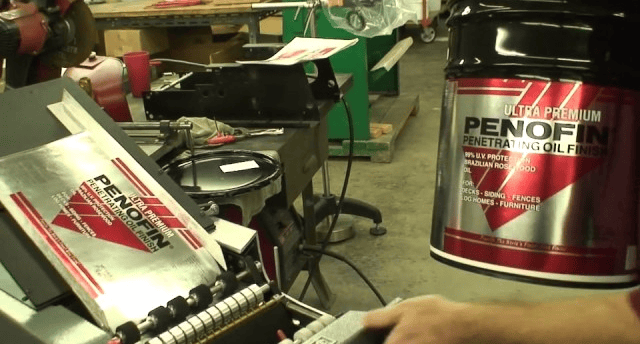

Advent Model 205

The Advent Model 205 is designed to label 5-gallon metal pails and stand containers. It offers exact placement of the label along the circumference of the pail. Glue is applied to only the ends of the label with its standard end gluing feature that requires no adjustments for different length labels. The machine does it automatically.

Advent Model 300

The Advent Model 300 Pressure-Sensitive Labeling Machine is unique when compared to other semi-automatic P-S labelers. With its ingenious design, air pressure and a label sensing switch are not required in its operation. Air pressure on other machines is required to lift the container up to the point of label application and then down where it is removed. This raising and lowering of the container wastes time. Advent has chosen to apply the label from the bottom of the container and use the weight of the container to press on the label. This method saves application time and increases labeling speed considerably. On other machines, the label sensing switch senses the space between labels on the label web in order to tell the machine when to feed a label. Advent does not require this switch which enables it to apply butt cut labels along with die cut labels. The Advent Model 300 is not a small table top labeler. This model is a production machine. It is designed for continuous operation.

Advent Model 310

The Advent Model 310 is what you might call an almost automatic pressure-sensitive labeling machine. Containers are fed into the machine by hand but are ejected automatically As the operator places the container into the machine the previous labeled container is pushed forward and onto a short gravity conveyor. If the containers are filled, they roll forward to the packing station. If they are empty, they can roll off into a box or go directly to the filling line. By handling each container only once, labeling speed is increased considerably. Speeds up to 30 to 40 containers per minute are not uncommon.

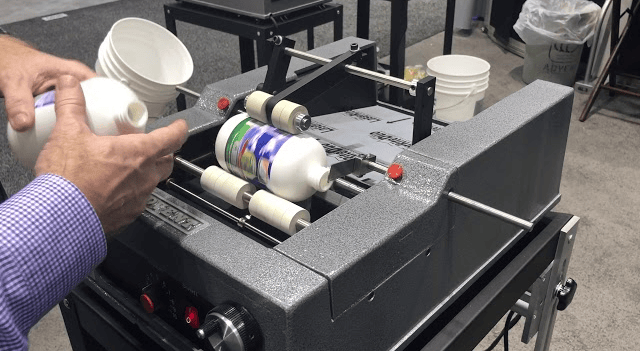

BOTTLEMATE 712M

If you are looking for a simple and versatile solution for applying labels to bottles, cans, jars or other cylindrical objects but you don’t want to spend a fortune, look no further! BOTTLEMATE by Labelmate is the Manual Label Applicator you need! A quick turn of the handle is all that is required to accurately and consistently place labels in the same location on all of your cylindrical objects. With BOTTLEMATE by Labelmate you will be able to easily label cylindrical objects with diameters ranging from 0.3” to 12” (size of a pen up to gallon size containers).

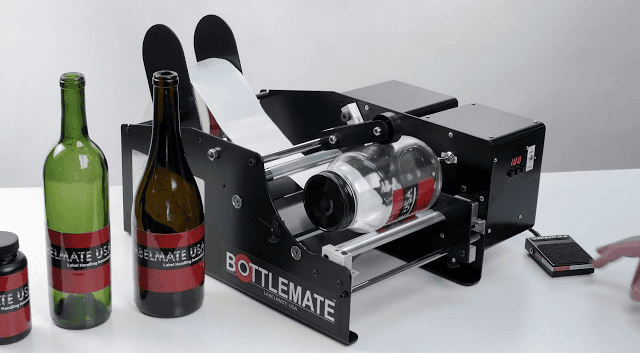

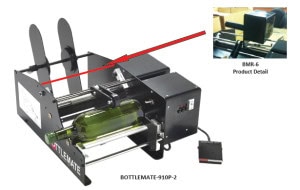

BOTTLEMATE 900 Series

If you are looking for a simple and versatile solution for applying labels to bottles, cans, jars or other cylindrical objects, look no further! BOTTLEMATE by Labelmate enables you to label all kinds of cylindrical objects by simply inserting the container and pressing a foot switch. Once the foot switch is activated the label is applied at over 4.5″ per second, and most bottles are labeled in less than 2 seconds! This allows you to quickly remove the bottle and insert another to start the procedure again. Once a rhythm is established bottles are labeled VERY quickly. The BOTTLEMATE can label products at speeds of up to 1200 Pieces an hour!

BOTTLEMATE 1500 Series

If you are looking for a simple and versatile solution for applying labels to bottles, cans, jars or other cylindrical objects, look no further! BOTTLEMATE by Labelmate enables you to label all kinds of cylindrical objects by simply inserting the container and pressing a foot switch. Once the foot switch is activated the label is applied at over 4.5″ per second, and most bottles are labeled in less than 2 seconds! This allows you to quickly remove the bottle and insert another to start the procedure again. Once a rhythm is established bottles are labeled VERY quickly. The BOTTLEMATE can label products at speeds of up to 1200 Pieces an hour!

BOTTLEMATE AUTO-MATE

The AUTO-MATE is an optional factory-installed accessory for all 900 and 1500 series BOTTLEMATES. The AUTO-MATE is installed on the Bottle Guide that abuts the bottom of the container and activates the unit automatically within 0.5 seconds when a container is placed on the rollers. Remove the container after it is labeled and repeat.

BMR-6 Liner Rewinder

The BMR-6 is an optional factory-installed Rewinder for all 900 and 1500 series BOTTLEMATES. The BMR-6 is mounted on a rod at the top of the machine and automatically rewinds the waste liner that is produced as labels are applied to containers. Without the BMR-6, the waste liner will simply fall over the back of the machine and onto the floor.

sales@marktecprods.com

sales@marktecprods.com