Trident Printhead High-Resolution Inkjet Printers

FoxJet ProSeries® 384e & 768e Hi-Res Printheads

New “E” series hi-res print engines from Foxjet print faster, farther away, and darker. This high-resolution industrial inkjet printer can keep up with the most demanding production line speeds while delivering high print quality! Foxjet “E” series printheads can be placed farther away from the substrate to be marked, protecting the printhead from damage due to misaligned cartons/trays. Additionally, the “E” series printheads prints darker for high legibility and better barcode read rates. Other improvements as well!

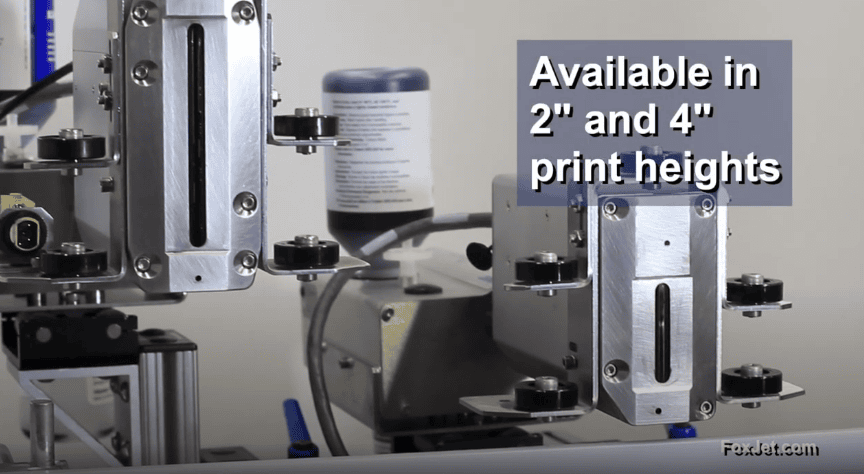

PROSERIES® 768E High-Resolution Inkjet Printhead: Enhanced for printing high-quality, complex messages utilizing a print height up to 4” tall. The ProSeries 768e allows manufacturers to replace costly labels with print-on-demand messages. Industry-leading ink throw distances allow the ProSeries Enhanced printers to offer the most forgiving distance tolerances between the printhead and product. Capable of providing maximum print quality on irregular surfaces. The ProSeries 768e model delivers superior performance when requiring large complex print messages consisting of graphics, logos, alphanumerics, and barcodes.

PROSERIES® 384E High-Resolution Inkjet Printhead: Enhanced for printing high contrast, high-quality barcodes, the ProSeries 384e allows manufacturers to produce scan-able and verifiable barcodes at the highest available speeds to achieve maximum throughput. With a 2” maximum print height, the ProSeries 384e model accommodates the tallest barcode standards and requirements.

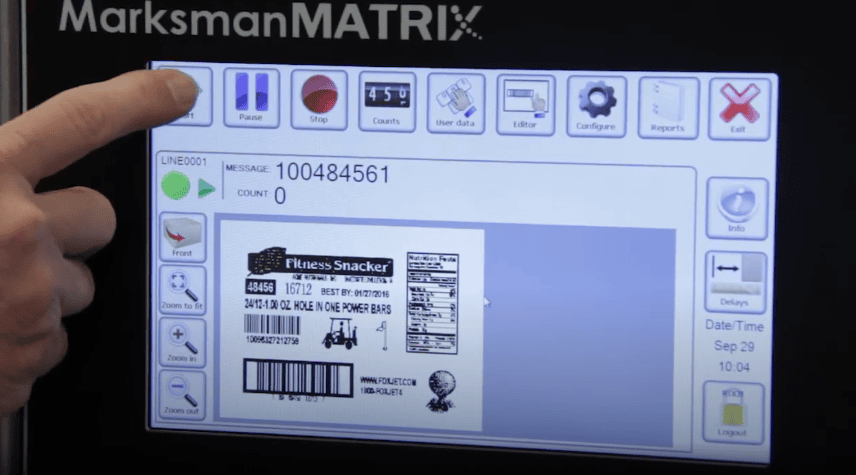

FoxJet Marksman Matrix™ Controller

FoxJet’s Marksman Matrix™ is a flexible, stand-alone high-resolution industrial inkjet controller. Capable of operating two production lines at the same time with up to four FoxJet printheads. The Marksman Matrix™ controls ProSeries Trident-based printheads. This enables them to print industrial compliant barcodes, graphics, and alphanumeric characters. Print on both porous materials and cases.

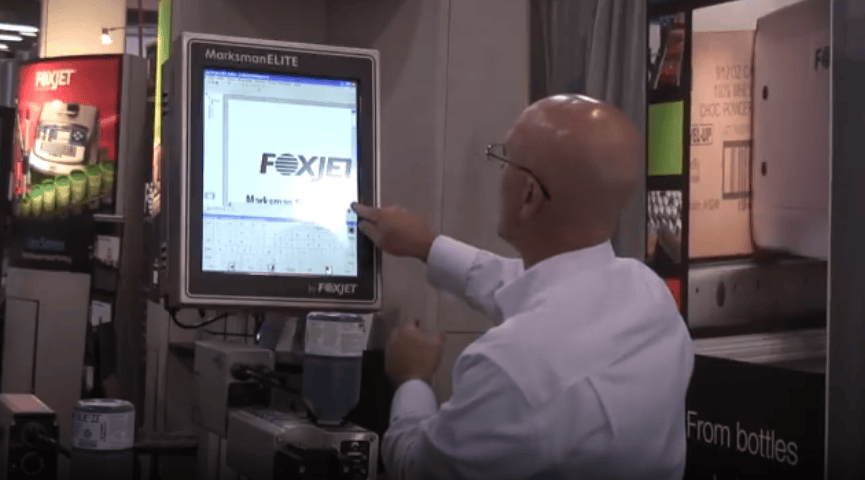

FoxJet Marksman ELITE Controller

FoxJet’s Marksman Elite Controller is a flexible, stand-alone high-resolution industrial inkjet controller. Featuring a 17” touch screen with an on-screen keyboard that allows for easy viewing and message creation. The Marksman Elite Controller controls the FoxJet ProSeries Trident-based printheads. This enables them to print barcodes, graphics, alphanumeric characters, and more. The rugged stainless steel case design captures all connectors inside. This keeps them free from exposure to moisture and dirt. Capable of operating two production lines at the same time with up to four FoxJet printheads.

Piezo High-Resolution Inkjet Printers

Squid Ink CoPilot® Max

Squid Ink’s CoPilot® Max utilizes oil-based or solvent-based inks. Capable of printing on a wide range of porous or non-porous substrates. Up to 2.8” of print height per printhead and the ability to run up to 2 printheads from one controller. A versatile yet cost-effective solution for your coding and marking needs. The CoPilot Max utilizes Squid Ink’s revolutionary active ink system. This allows users to tilt or rotate the printhead in any direction without having to make height adjustments to the ink supply system. Print hi-resolution characters, text, barcodes, and great-looking logos at up to 360 dpi. That’s almost twice the resolution of competitive printers in its class!

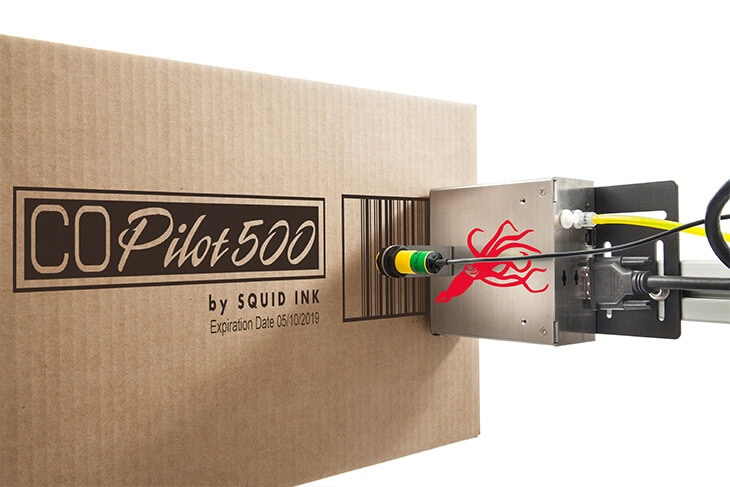

Squid Ink CoPilot® 500

Squid Ink’s CoPilot® 500 printing system is a high-resolution industrial inkjet printer. Featuring up to 2.8” of print height per printhead and the ability to run up to 2 printheads from one controller. This provides a total print height of 5.6″. A versatile yet cost-effective solution for your coding and marking needs. Capable of using oil-based or solvent-based inks for both porous and non-porous surfaces. A simple ink delivery system features a large 500ml cartridge. Enables you to keep your line running and reduce downtime.

sales@marktecprods.com

sales@marktecprods.com