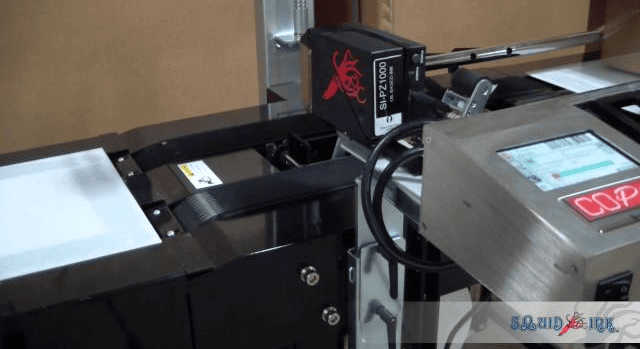

Squid Ink CoPilot

Squid Ink’s CoPilot uses proven Xaar piezo technology to print up to .7” of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi and a 4.3″ full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. For larger applications, multiple CoPilot printing systems can be connected via Ethernet or wirelessly and controlled through one central Orion print station.

Squid Ink CoPilot 128

The CoPilot 128 ink jet printing system offers the durability, versatility and productivity that you have come to rely on from Squid Ink. Whether you are printing lot codes on coated cartons, bar codes on corrugate cases, or product information and logos on PVC pipe you’re sure to find the right solution with Squid Ink’s new CoPilot 128.

Squid Ink CoPilot 256

The CoPilot 256 ink jet printer is designed to print superior quality hi-resolution characters on either porous or non-porous surfaces. With up to 2.8” of total print height and the ability to print on both sides of the substrate in a single pass, the CoPilot 256 is designed to work as an integral part of your day-to-day packaging operation.

Squid Ink CoPilot Flex

The CoPilot® Flex is designed to print superior quality hi-resolution characters, razor-sharp text, real-time information, scannable bar codes, and great looking logos on pulp, foam, or PET egg cartons. With up to .7” of print height and the ability to print multiple lines of information in a single pass, the CoPilot Flex is designed to streamline your printing process.

CoPilot Flex is engineered for simple integration on your existing egg packing line or wherever space constraints are an issue. The system’s unique and compact design allows for narrow mounting in nearly every zone of your egg packing process, eliminating the need for after-market engineering or time-consuming modifications to your existing conveyor. CoPilot Flex’s small printhead adjusts to match the slope of the carton to ensure a quality hi-resolution print. The system is capable of inverting your printed message, if needed, meaning you can print your cartons in the open or closed carton zone. At print speeds of up to 135 ft/minute, the CoPilot Flex is sure to keep your production moving.

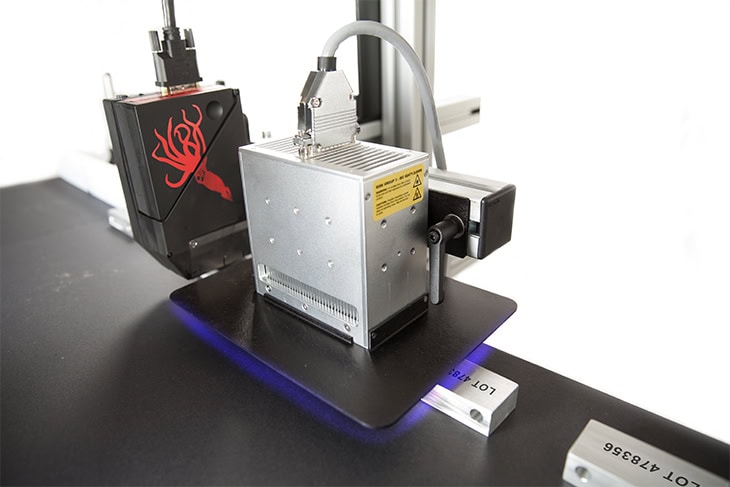

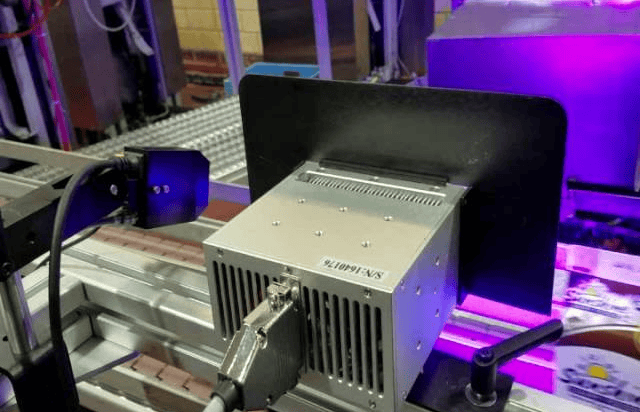

Squid UV LED Curing System

When you need your mark to be highly resistant to an alcohol wipe for medical equipment applications and demanding automotive applications where your mark is exposed to freezing, wet, solvents, and other conditions, or needs to dry immediately on glass, metal, plastics, and other surfaces, the Squid UV ink curing system (LED Lamp and printer) was designed to perform under these harsh environmental and demanding conditions. Print sample testing is always recommended for validation and it is available at no charge! Please contact us with your specific requirements. This Squid UV printer is an outstanding system to use for these applications.

Squid UV is capable of curing inks in a 20mm x 80mm area from a single illumination module that can be doubled to cure an area of 40mm x 80mm or 20mm x 160mm with the addition of a second system. The system features an advanced LED module to provide consistent luminance, resulting in a reliably cured product, every time. The stability of UV LED technology makes the output of electricity predictable and stable, avoiding problems associated with conventional halogen heat lamp drying.

UV LED technology provides a stable and efficient way of curing CIJ, Piezo, and Thermal inkjet inks. The integrated super cooling system considerably lowers the unit’s operating temperature to extend the life of the machinery while reducing maintenance costs. The use of UV LED curing results in a significant savings in power reduction, and time and money spent replacing lamps becomes obsolete due to the 20,000+ hour illumination runtime. For comparison, Squid UV curing systems use about 75% less energy than typical UV arc lamp curing.

sales@marktecprods.com

sales@marktecprods.com