Our new products we now offer for marking and labeling equipment!

Squid Ink CoPilot Max

Squid Ink’s CoPilot® Max uses proven Xaar piezo technology to print up to 2.8” vertical height of Hi-Resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 360 dpi. A 4.3″ full color touchscreen provides access to the system’s internal messages and print

functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. Multiple CoPilot printing systems can be connected via Ethernet or wirelessly and controlled through one central Orion print station.

Squid Ink SquidCheck Print Validation System

SquidCheck™ offers print and verification of the bar codes printed on your cases, trays, pipe, or other products. SquidCheck utilizes bar code readers from Cognex®, the world’s most trusted machine vision and industrial bar code reading company. The reader is integrated with a Squid Ink printer and SquidCheck interface to ensure that codes are present, scannable, and accurate.

R321 automatic inline pressure sensitive labeler

This engineered pressure sensitive labeling system is designed to label round bottles and containers. It automatically applies die cut pressure sensitive labels to cylindrical containers.

Squid Check

SquidCheck™ offers print and validation of the bar codes printed on your cases, trays, pipe, or other products. SquidCheck utilizes bar code readers from Cognex®, the world’s most trusted machine vision and industrial bar code reading company. The reader is integrated with a Squid Ink printer and SquidCheck interface to ensure that codes are present, scannable, and accurate.

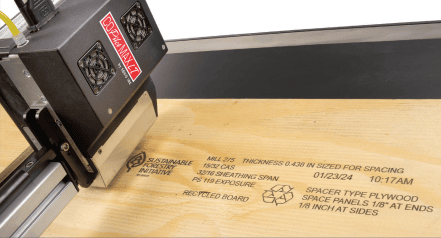

CoPilot Max LT

Squid Ink’s CoPilot® Max LT long throw printing system has redefined the hi-resolution industrial ink jet coding and marking industry with an unprecedented 10-12mm throw distance. That’s up to .5” away from the substrate, ideal for overfilled cases, angled or recessed surfaces, irregular

shaped products, or inconsistent product handling. Extended throw distance is also helpful to protect the printhead from fast moving cases or heavy industrial products. Of particular note is that the Max LT print speed is up to 220 ft/min at 300 dpi resolution for barcodes and graphics, and up to 440 ft/min at 150 dpi resolution for text to meet almost any speed requirement.

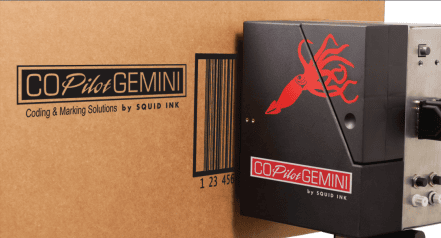

CoPilot Gemini

Squid Ink’s new Hi-Resolution CoPilot Gemini printer has a large vertical print area of 5.6.” This capability enables you to replace your preprinted shipping cases and large labels. Now you can stock blank generic cases and print directly on your cases, on-demand, just-in-time, in any quantity. Vertical print resolution is 360 dpi. Case SKU’s can now be case sizes, instead of many product SKU’s. The cost savings is significant! You can use your CoPilot Gemini on your production lines and also on an Eastey off-line Vertical Case Transport System (VCTS) and use one Gemini printer to print cases for all of your production lines and hand pack stations.

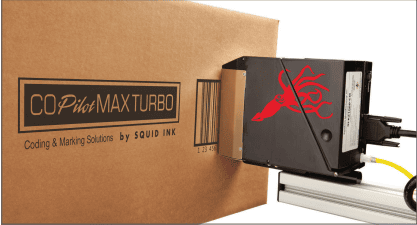

CoPilot Max 512i Turbo

Squid Ink’s CoPilot® Max 512i Turbo printing system is designed to print superior quality hi-resolution characters on porous or non-porous surfaces. For applications that require immediate dry times on non-porous surfaces, the CoPilot Max 512i Turbo also has the capability to run UV LED curable inks. With up to 2.8” of print height per printhead, print speeds up to 480 ft/min, and the ability to run up to 2 printheads from one controller, the CoPilot Max 512i Turbo provides a cost effective solution for making your mark on a wide variety of products and substrates.

Mineral Oil Free Inks

Consumers want “Environmentally Friendly” products in almost every category.

This is especially true in Food Processing facilities all over the U.S.A, and the world. Their consumer customers want safer everything.

Ink Jet Case Coder ink is no exception. Ink vapors in the air can sometimes bond with products and impact product quality and taste and some inks have hazardous ingredients stated on their SDS safety documents.

GSI Colorize Ink Jet Printer

What is a GSI COLORIZE Ink Jet Printer all about?

It’s no secret that color really helps sell consumer products!

That color is typically printed on the outside of a white or brown carton or smaller white set up boxes.

Preprinted corrugated cases and glossy boxes are expensive. You need a preprinted case for every SKU you sell in those boxes.

GSI No Label Ink Jet Printer

NOLABEL ink jet printers – why are they needed?

Walmart, Target, and other consumer goods retailers have automated their receiving at their Distribution Centers.

They are using scanners on their conveyors to scan barcodes on boxes that are being unloaded. They want white labels with barcodes printed on them. Pressure sensitive printed labels are expensive especially when you are labeling thousands of cases. Labels required on two sides of a case are twice as expensive.

sales@marktecprods.com

sales@marktecprods.com